In collaboration with consultants at CNH Industrial and Italian alcohol model, Martini, two teams of Industrial Design Masters college students at Italy’s Istituto Europeo Di Design got the duty of designing an agricultural car that not solely improves the effectivity of farming duties, but in addition the working circumstances for operators

In 2024 the CNH design workforce as soon as once more collaborated with Istituto Europeo di Design (IED). Along with its undertaking accomplice, the historic Italian model, Martini, CNH Industriaal challenged college students on the grasp’s course in Transportation Design to reimagine a self-propelled grape harvester.

New Holland has over 50% of the worldwide market on this product phase and the scholars had been tasked with discovering progressive methods to enhance the harvesting course of, whereas additionally bettering working circumstances. They had been additionally challenged to combine new know-how and sustainable supplies.

The scholars carried out thorough analysis and developed artistic concepts for a flexible machine aimed toward enhancing each working circumstances and productiveness. The purpose was to create a brand new kind of harvester that bridges the hole between hand-picking and mechanized harvesting. Emphasising sustainability and leveraging superior know-how for max effectivity had been major concerns. Two groups of design college students crafted their distinctive imaginative and prescient of the longer term.

Challenge SideWays

This workforce, comprised of scholars Alessandro Ravedati, Francesco Raffaele, Megh Bathtub and Santiago Espindola, got down to enhance the working circumstances of guide grape harvesting.

Grape harvesting is commonly executed on hilly terrain, which isn’t very best for giant, mechanized harvesters, nonetheless guide harvesting is gradual, expensive and creates plenty of human fatigue.

To handle this case, the designers studied the varied ache factors and created a small machine that’s able to getting into into smaller vineyards. The machine can work on inclined fields because of the gyroscopic suspension system, whereas the operator stays in a cushty upright place. Physique help safety helps considerably to enhance working circumstances.

Displaying that good design can create a harvester with type, the workforce had been impressed by the Martini bottle, mixing this inspiration with essential features. The machine is absolutely electrical and runs autonomously, permitting the operator to deal with the grape selecting at an excellent top and posture. A storage container is built-in into the machine to obtain the grape assortment and particular flotation tyres along with rear tracks assist to minimise soil injury. Clever glasses can be utilized together with the Shear Glove to detect and minimize the right grapes to guarantee that the harvest is of top of the range.

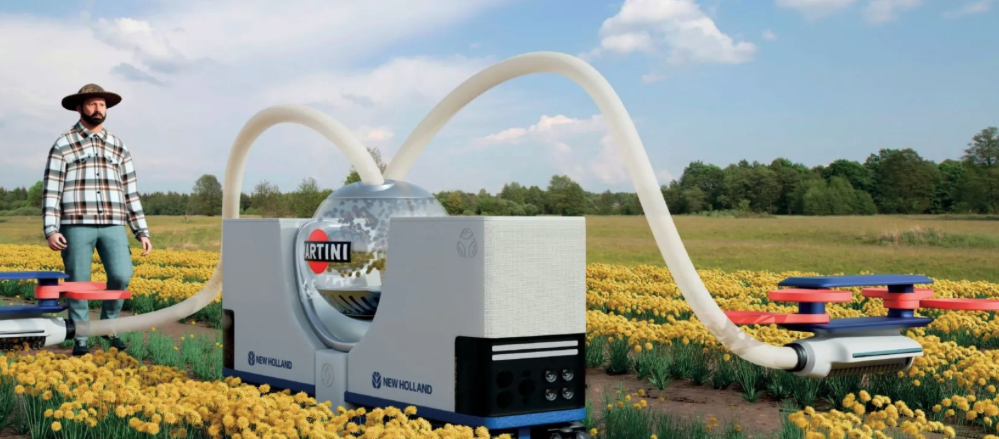

Challenge Herbini

CNH’s different workforce of design college students, together with Marina Cerfeda, Marica Flagiello, Jorge Garcia Del Rio and Felipe Rey Barberi, created an autonomous system for harvesting fragrant herbs. This method has been designed to work in a two-hectare area comprising 90 rows with 65kg of flowers in every. Every storage field has the capability to carry one row of flowers.

Flying electrical drones information harvesting rollers which, with the assistance of sensors, decide solely the herbs which might be prepared for harvesting. As soon as collected, herbs are swallowed up by tubes linked with the ‘alambicco’, which brings the flowers into the storage packing containers. As soon as these packing containers are full, they detach from the rover autonomously, reaching the in-field assortment level. Within the meantime, an empty, alternative field reaches the rover via a community of sensors and GPS indicators.

The system is supplied with two harvesting drones and packing containers, which lower the harvesting time by 50%. The inspiration comes from the ingesting experiences of Martini and the preparation of vermouth contained in the manufacturing facility. The central aspect of the system is ‘alambicco’: the form recollects the Martini glass and the copper nonetheless, whereas the tubes are harking back to straws in cocktails.