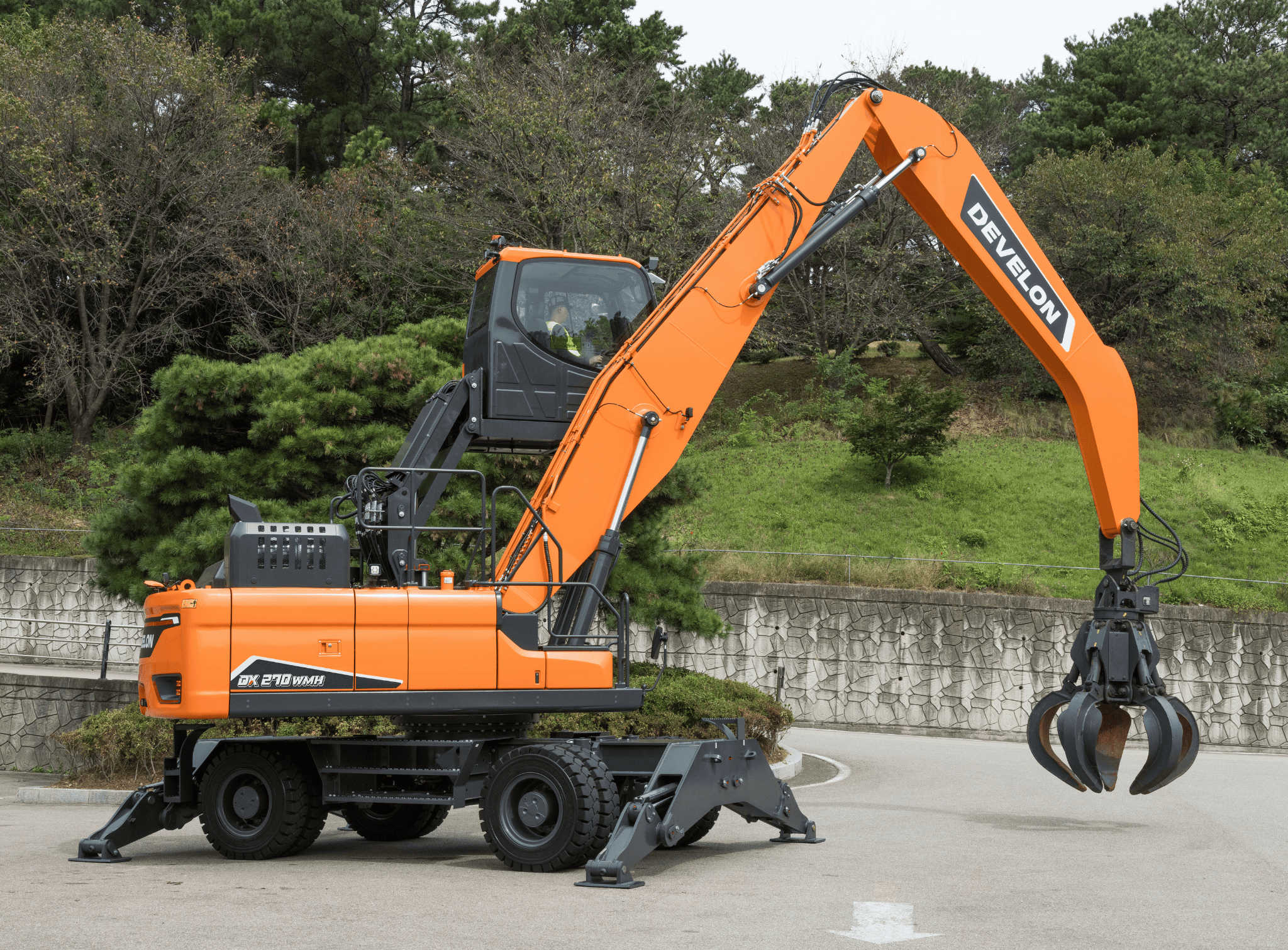

Develon has launched the brand new DX270WMH-7 wheeled materials handler. The DX270WMH-7 is powered by the most recent era Develon 6-cylinder, turbocharged DL06V water-cooled diesel engine, offering an output (SAE J1995) of 141kW (189HP) at 1900RPM.

Incorporating new undercarriage, arm and increase, elevating cab and counterweight designs, the brand new DX270WMH-7 is constructed to supply subsequent stage efficiency for the hardest duties throughout a variety of fabric sorting and dealing with purposes. The latter embody the dealing with of scrap metallic and different strong waste, in addition to these in recycling, demolition and the timber trade.

The DX270WMH-7 has a newly designed undercarriage with heavy obligation, extensive axles and longer and broader dimensions, mixed with an identical wheelbase to offer enhanced stability when working with the machine.

With a spread of elevation elevated to 2603mm, the brand new hydraulic cab riser design provides the operator higher all-around visibility of the attachment and work space. That is mixed with a quicker up velocity for the elevation.

The very newest DXW-7 cab design offers a snug inside and ergonomic format, together with an 8 inch gauge panel and good controls offered by the very newest working expertise.

The elevating cab incorporates structural reinforcements to make sure smoother operation and supply higher safety of elements reminiscent of hoses and greasing strains. There are additionally two security valves for emergency cab descent, one within the cab and the opposite on the surface.

The DX270WMH-7 affords a vastly improved efficiency with out compromising on dimensions, with an extended attain and a better lifting capability, with a straight arm as commonplace and the choices of gooseneck and lengthy gooseneck arms as alternate options.

The straight arm configuration affords the bucket linkage and commonplace coupling for the usage of sorting grapples. The gooseneck arms present an economical answer, to be used the place suspended attachments are being employed. Arms and booms have been designed particularly for materials dealing with duties, with the emphasis on sturdiness and lifting stability.

The brand new materials handler has been designed to be simple to function with ergonomic joysticks and a steering wheel. The machine comes geared up with two-way auxiliary and rotate circuit hydraulics to enhance effectivity. The operator can use buttons on the joysticks or an elective foot pedal to regulate auxiliary attachments.

A particular Develon-developed system, Sensible Energy Management (SPC), improves machine effectivity whereas sustaining productiveness by way of variable velocity management and pump torque management, robotically adjusting RPMs in response to the load being dealt with.

Constructed on years of expertise with earlier fashions, the DX270WMH-7 is engineered particularly for the demanding wants of waste and recycling operations. Its extensive and steady undercarriage with individually managed stabilizers ensures distinctive stability and sturdiness, even in uneven or debris-laden environments. A reversing fan comes commonplace, serving to to take care of optimum engine temperatures by robotically clearing mud and particles from the cooling system – minimizing downtime and upkeep.

To reinforce operator and web site security, the machine options an revolutionary digital wall system, permitting for customizable working boundaries to stop unintentional contact with obstacles in entrance of the machine or with ceilings when working indoors. The system additionally prevents the chance of contact of the attachment and the cab with the environment.

Photos courtesy of Develon